x Circular Economy

At Disobedience, we believe fashion shouldn’t cost the earth. From day one, our goal has been to create desirable shoes with a low environmental footprint designed not just for wear, but for disappearance.

We chose to manufacture in-house to avoid the overproduction and waste typical of factory-made collections. This gives us the freedom to experiment with new materials and refine our designs something we’ve been committed to for over four years.

Our shoes are made to be worn, repaired, and eventually dismantled—so their components can live on or return to the earth.

That’s why we prioritize biodegradable materials. With textile waste making up nearly 5% of landfill volume, we choose materials that naturally break down—reducing long-term pollution and helping close the loop.

Disobedience means rejecting wasteful norms. Our circular design approach is our quiet rebellion—against excess, against pollution, and for a better future underfoot.

Materials Used

Hand Spun and Hand Woven Kala Cotton

Organic Kala cotton, an indigenous and sustainable crop grown in Gujarat, forms the core of our textile offering. We collaborate with skilled weavers from the Bhuj community who hand-spin and hand-weave the fabric using traditional techniques. The process requires minimal machinery and energy, relying instead on manual labor, which significantly reduces its environmental impact.

Plant Leather Alternatives

We work with select Indian suppliers of plant-based leather alternatives made from banana waste, tomato peels, and sugarcane bagasse. These materials are 85% biodegradable and repurpose agricultural waste that would otherwise be burned, turning it into sustainable raw material for footwear.

Hand Spun and Handwoven Desi Wool

Another regenerative, low impact material, which is un-dyed and used in its purest form is black sheep wool collected from pastoral communities

Cellulose Sheets

They are a sustainable alternative to synthetic materials like plastic. Cellulose sheets exhibit good mechanical properties, flexibility.

Upcycled Plastic Textile

Plastic waste, which are difficult to be recycled , which otherwise would be in landfill. These are handwoven and hand twisted into yarns so energy consumption is close to zero and we have a collection made from this upcycled plastics.

Reclaimed Wood & Upcycled Steel Waste

Reclaimed teak wood procured from timber houses. These are rejects, we upcycle these into our customised heels .

Upcycled steel waste from fabrication industry : our steel heels are made from metal scraps generated in fabrication units in Chennai.

Techniques Implemented

We treat waste as raw potential. Using low-impact, hands-on techniques, we upcycle plastic, textile scraps, agri-waste, and reclaimed wood into thoughtful shoe components proving that discarded doesn’t mean useless.

Upcycling Plastics into Textile

The non recyclable plastic wastes that are sent to landfill is collected, cleaned and cut into strips and then hand twisted into yarns and then handwoven on pit looms to create plastic textile sheets

Upcycling Textile Scraps for Surface Design

We work with textile designers to upcycle our textile scraps created during the shoe stitching process, to create surface designs on shoes using this scraps, we have also tried using pistachio shells as embellishments

Plant Leather from Upcycled Agricultural Waste

We work with partners who upcycle the agricultural waste like tomato scraps, sugarcane bagasse, banana crop waste – which otherwise would be burned by farmers. These upcycled agri waste is made into leather alternatives

Upcycling Teak Wood from Timber Houses

We source reclaimed teak from timber houses, where large wood logs are cut. The off-cut blocks are used to craft our heels, and even the leftover skeletons from CNC cutting are repurposed to create new ones.

Upcycling the scoring waste from footwear industry into bonded sole sheets

We have partnered with P A footwear + CLRI-NIIST in developing bonded sole sheet from scoring waste generated in a shoe factory, this is a pollutant and our collaborators have found tech to make a product

From handwoven plastic textiles to bonded soles from factory scraps, every technique we use helps close the loop. Through craft and collaboration, we turn waste into lasting design. One step at a time.

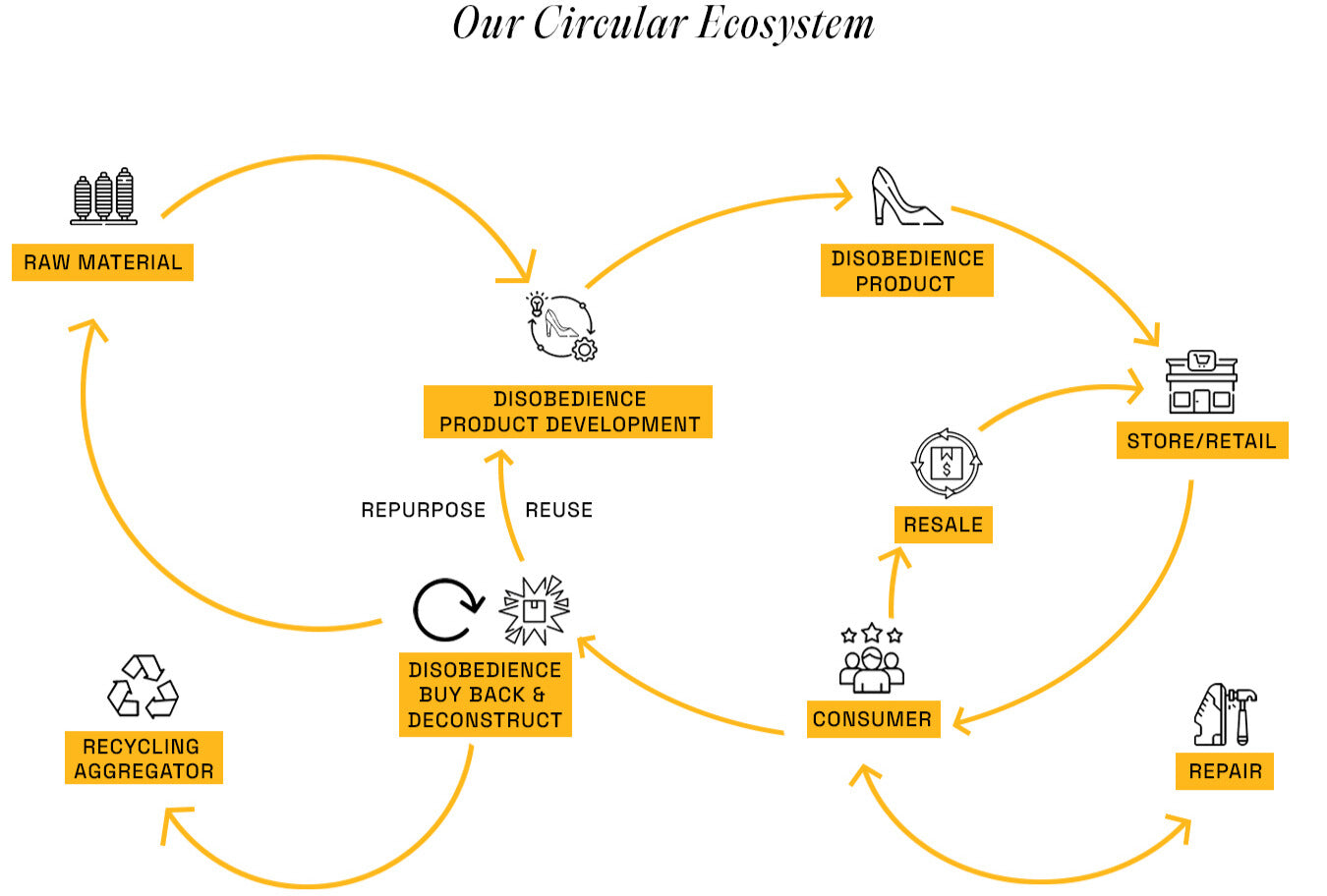

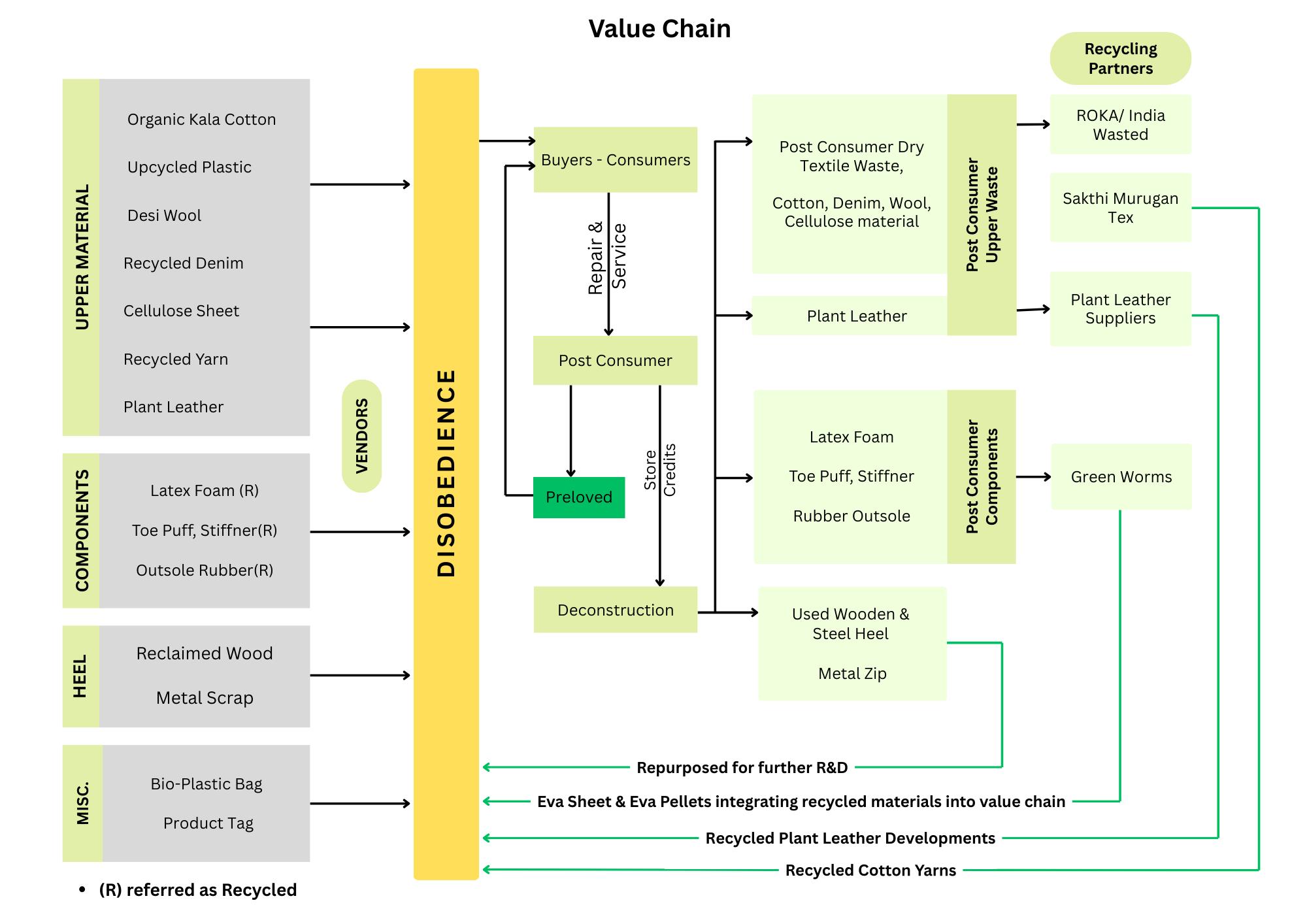

The Circular Economy of Disobedience

Disobedience is built on a simple idea: nothing should go to waste. We use biodegradable, regenerative, and upcycled materials, paired with low-impact, repairable construction. From agri-waste leathers to reclaimed wood and recycled plastics, every shoe is made to last — or return to the earth.

Circularity isn’t a feature. It’s our foundation.

Repair

We offer a 2-year service warranty with every pair, along with a mini service kit. Certain models allow heel replacement and textile mending — extending the shoe’s life without full replacement.

Upcycle

We upcycle textile scraps into new fabrics, use pistachio and sea shells for embellishment instead of plastic, and craft heels from reclaimed teakwood scraps — proving waste can be beautiful.

Recycle

Through partnerships with Green Worms and PA Footwear, we recycle post-consumer shoes and integrate recycled materials — from latex foam and PET-based yarns to rubber soles and thermoplastics — into our production chain.